What Happened to Making Steel in Baltimore? – Mark Reutter on Reality Asserts Itself (1/3)

This interview was originally published on February 23, 2015. Mark Reutter, author of Making Steel: Sparrows Point and the Rise and Ruin of American Industrial Might, talks about why steel production collapsed across America.

PAUL JAY, SENIOR EDITOR, TRNN: Welcome to The Real News Network, and welcome to Reality Asserts Itself. Sparrows Point is an industrial location just outside of Baltimore City. In the late 1950s, Bethlehem Steel had 30,000 people working there. By 2012, there was nobody. To help tell us the story of why and how that happened and could public policy have made a difference, joining us in the studio is Mark Reutter. Mark has been reporting and writing on Baltimore since 1970, when he started as a 19-year-old summer intern covering cops for The Evening Sun. He later moved on to The Baltimore Sun, where he was a reporter for eight years. In addition to his writings on Baltimore, he’s edited the historical magazine Railroad History and is the author of Making Steel: Sparrows Point and the Rise and Ruin of American Industrial Might. And he’s the senior writer at the Baltimore Brew, which is doing the best investigative journalism in the City of Baltimore. Thanks for joining us.

MARK REUTTER, EDITOR AND SENIOR JOURNALIST, BALTIMORE BREW: Thank you.

JAY: So your book is about, like, this thick, so you can’t give us all the detail. But give us, first, to start conversation, just the big brushstrokes of why steel collapsed, closed in Baltimore County.

REUTTER: The broad brush stroke is that steel was the biggest basic industry in the first part of the 20th century. It was the foundation of, really, modern society. But things began to change after that. Technology moved on. There were other materials, aluminum, plastic, and others, that began to be developed, and these began to impinge on this huge industry that had a basic monopoly for many, many years. Faced with that competition and change, the steel industry, both at Sparrows Point and around the country at these big installations–Chicago, Pittsburgh, etc.–stayed put. And they just put their feet down, they decided that no one was going to dislodge them, that it was foreign competition and government overregulation that was the cause, and they weren’t about to change. Finally, they just cannibalized themselves, and eventually the mill was just a mishmash, at its very tail end it was a mishmash of old and new, and basically leaking money throughout the whole process.

JAY: Now, steel production moved, to a large extent, to Asia and some other places. There’s lots of steel being produced. There’s lots of steel being used. Why couldn’t it be here? I mean, one of the arguments one hears is that it’s–essentially was the cost of labor, and so China’s cheaper labor, so China’s kind of–because nobody would defend the American steel market, it’s really–China is the reason for the demise of American steel.

REUTTER: Well, going out of World War II, the U.S. had around 60 percent of the world’s steel production. And a part of that was, yes, Europe had destroyed itself during the war. One little-known fact is that the U.S. steel industry then doubled its actual production between 1945 and 1960, but it doubled it in old technology while things were massively changing, and their costs did get too high. You and probably some of the listeners will remember, if you go back, not just with President Kennedy, but how once a year, U.S. Steel would announce a price increase of 5 or 6 percent for hot-coiled steel, and within hours every single of the other so-called big steel companies–Bethlehem, Inland, Armco, Jones and Laughlin–all kind of lost names–all did the same lockstep. And so a lot of it had to do is that the U.S. steel companies priced themselves out of the business and they didn’t innovate.

JAY: Well, so there’s two different pieces here. There’s the cost of labor, and there’s innovation in technology. So let’s start with what is usually talked about, which is that labor costs were too high and the American worker just cost way more than the Chinese worker, and that’s the reason steel left. I hear that all the time.

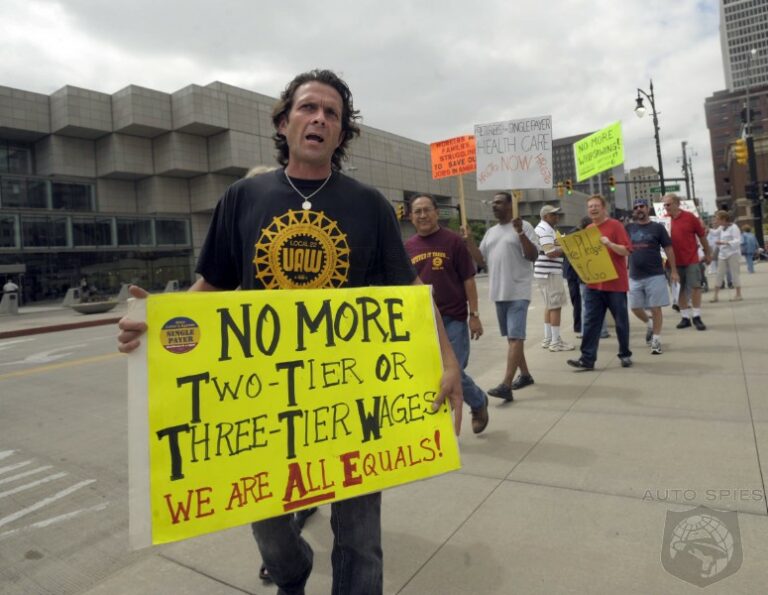

REUTTER: Well, eventually that became the case. But let’s go back. Back in the 1950s, there was also the very strong steelworkers union, which came out of John L. Lewis and the coal miners. And they became known in the ’50s under their president, McDonald, as the business union. They were always compared to Walter Reuther and others and coworkers–gee, those guys go on strikes, they have progressive ideas, but the Steelworkers are a business union, it’s all meat and potatoes, dollars and cents. At the same time, the steel industry would raise its prices year after year in lockstep. They would give raises to the steelworkers union. And the two of them really worked in collusion, because both of them believed that steel was essential and that it would never go away. The first challenge to the supremacy of Sparrows Point came in the 1960s. And it came not from–well, China didn’t have a steel industry then. It didn’t even come from Japan or Europe. It came from a company in Richmond, Virginia, called Reynolds aluminum. Reynolds developed a new type of orange juice can using aluminum and extruded an aluminum that, while much weaker than steel, had certain properties that bottlers or canners National Can, Continental Can had been asking steel to do for years, and they said, tough, we’re going to do it the way we’ve always done it. Sparrows Point lost the orange juice bottling or canning market. They then lost the soft drink, Coke, Pepsi canning market. They then lost the beer canning market, which was the very market that was of extreme importance to Sparrows Point in getting it through the Depression in the 1930s, where they had done some innovation and gotten large quantities of cans to be produced after the end of prohibition. So there really was a huge technological side. And going back to labor, here’s a really great story. Sparrows Point had 3,000 men, all men, who worked in the open-hearth furnaces. They were the largest open hearths in size in the world. They were gigantic. They were also–they could produce 400 tons of steel, but it would take them eight hours to do this. The basic oxygen furnace that could produce much less but much faster was coming in in Europe. But Sparrows Point opted in the late ’50s to produce, to buy even more and install even more of these open hearths. So they had 4,000 workers, heavy dangerous work, but here’s the most interesting thing. The man who was the superintendent of that, I was told by many people, was the most opposed to any sort of job or cutbacks or changes, because by having 4,000 men in his unit, he was able to sit at the first table at the private country club facing the general manager, and he wanted to keep his seat at the table.

JAY: There seems to be two theories of what happened in the broadest way to Sparrows Point. One is American workers priced themselves out of the market. The other is on the side of innovation, but essentially investing in new technology. That really is what made steel uncompetitive, especially with rising Japan and China, that they just leapfrogged to much more efficient technology, and that it could have been done here.

REUTTER: Oh, absolutely. Absolutely. The other problem was not just that they were able to leapfrog a new technology. That’s true, although, surprisingly, China to this date uses open-hearth furnaces. It has an awful lot of very old technology. And a very cyclical industry, steel. When steel was booming, even ten years before the demise of Sparrows Point, this very old equipment could make money. And that’s what sort of was the rationale [incompr.] stayed on. What was going on with management and with unions and with this kind of inherited power they saw, and that they worked in a world that was really surrounded by massive machinery, was on its own peninsula, it was smoky and clouded all day long, they worked 24-hour shifts where they oftentimes didn’t see their families–there was a mentality. This is what I picked up and write about in my book and was the most striking thing from the literally hundreds of interviews I had over the ten years I worked on this book, because I got so fascinated with the culture. What fascinated me was the technology was all there, the money was there. Bethlehem had tons of money. What was lacking was the willpower, the ability of these strong men, who prided themselves on their strength, to see the future.

JAY: I mean, just they’d been monopolies for so long, they just felt there was never going to be a challenge.

REUTTER: When the final incarnation of Sparrows Point, this kind of ramshackle company called RG Steel, declared bankruptcy in 2012, thus ending on a very ignoble note the end of steelmaking 120 years at this Peninsula, around a month after that happened, the steelworkers held a meeting where a disastrous thing happened. Much to their surprise, no big steel company or small steel company stepped in in bankruptcy court in Delaware and said, I want Sparrows Point. Instead, two liquidators came in and grabbed the plant at a bargain basement price. There was a union meeting where the union went to tell the workers that everything was over, everything was gone. They were–again, the union was so uninvolved and outside of its own politics that no press or anyone could go into this. Well, there was no problem there. I slipped right in in my cap and everything. And so I listened to it all. And men were getting up and saying, well, why didn’t I get my vacation pay last week? They were still arguing over this and that. And it was over. What the union wasn’t explicitly telling them, what Baltimore Brew was then writing, was: you not only lost that, but the new company signed an agreement that all previous labor agreements were over and done with. They were gone. They weren’t going to get a pension, they weren’t going to get anything. And vacation pay was the least of their problems.

JAY: Thanks for joining us.

REUTTER: Well, thank you. I enjoyed it.

JAY: And thank you for joining us on The Real News Network.

Mark Reutter is an author and journalist. He is a senior writer at the Baltimore Brew and previously worked as a reporter at the Baltimore Sun. In addition, he is the author of Making Steel: Sparrows Point and the Rise and Ruin of American Industrial Might.